OSHA Off Site Performance Centre (OPC)

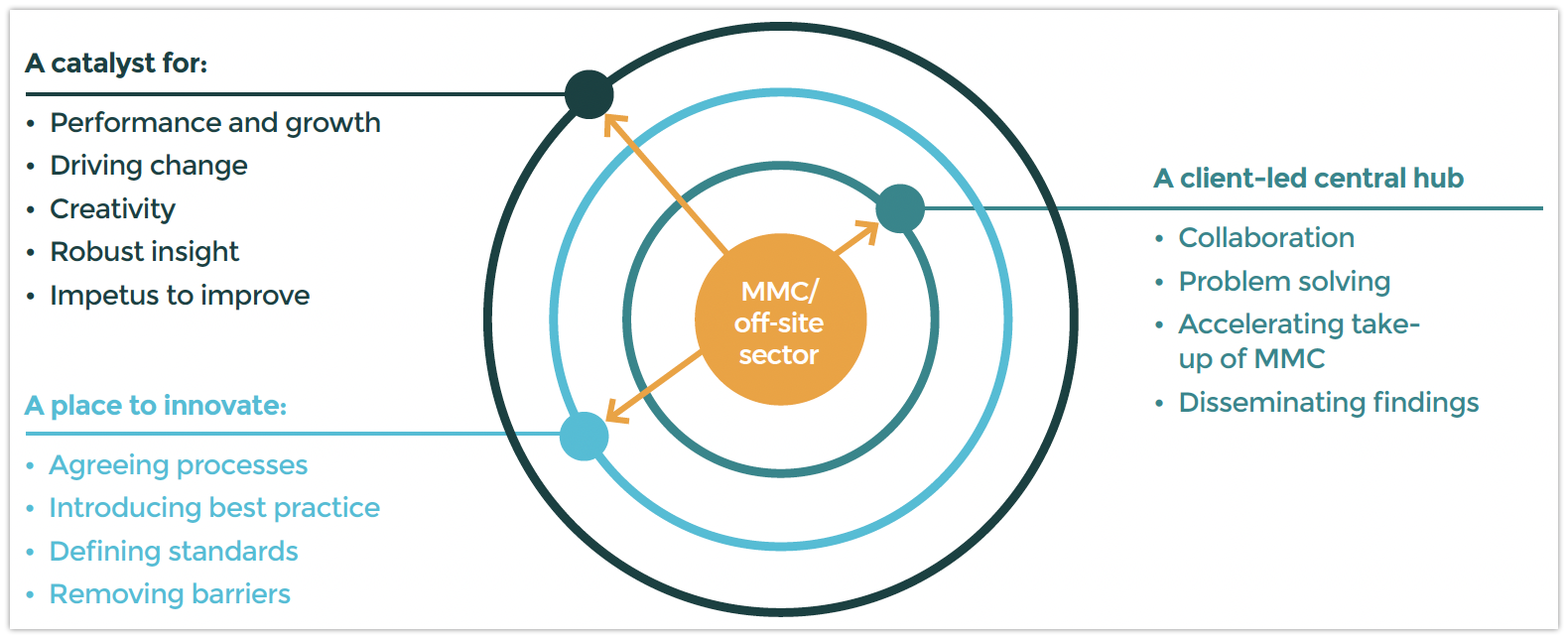

OSHA in final discussions with numerous industry partners and government agencies to set up an initiative, which we are calling the ‘Off Site Performance Centre’ (OSHA OPC).

OSHA will use the power of its network partners already committed to the OSHA collaboration and many other well researched and well established stakeholders, who have now expressed a strong desire to involve themselves in the proposed OSHA OPC, to remove barriers to growth in MMC housing. With a place to discuss, innovate and resolve, OSHA can then focus on maximising the output of the OSHA Platform including the OSHA £2Bn MMC Framework, where supply of affordable, high quality and real performing homes, are then the primary focus, rather than the delivery process itself.

The strategy behind this initiative, is to work with existing organisations and experts in the field, to bring together the strength of our knowledge and experiences, rather than to set up yet another entity to try and drive performance and growth in a silo manner. Our primary and secondary research (business case) confirmed that this is very clearly a network of like-minded organisations all with the same goal, often with close connections to each other, yet there is no one place to connect our national thinking, efforts and drive for ultimate solutions to working together on the DfMA approach to housing supply.

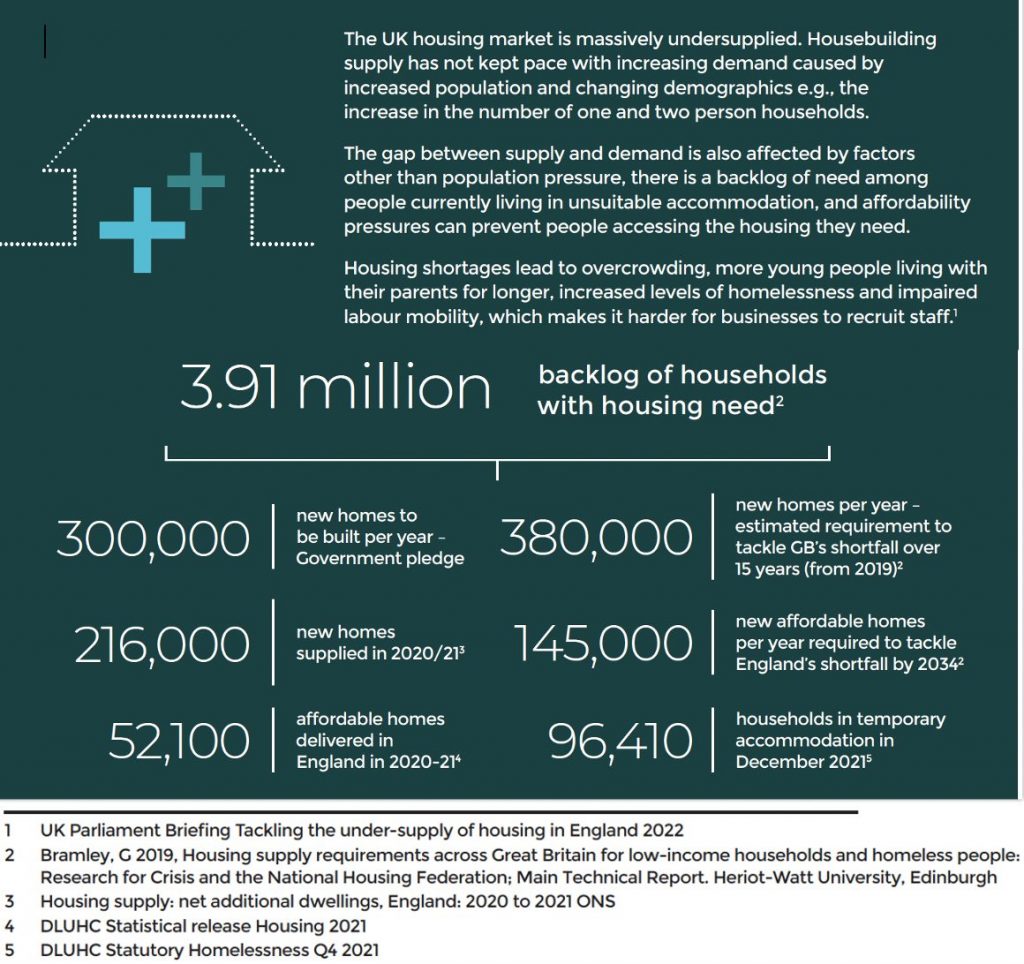

Our past business case research and deliberations – There is clearly now, a much better way of designing, manufacturing and assembling homes with significantly enhanced control over compliance and quality using MMC DfMA techniques, with much smarter ways for the compliance organisations to audit and approve them for asset management and securitisation. However, nearly all standards relating to Building Regulations, Construction Products Regulations and contractual agreements, were developed for traditional building practices, rather than specifically for MMC. With the very well understood and documented pressures on our traditional routes to market (skills and labour shortages, slow build times, quality issues on building sites etc) and the severe shortfalls in housing provision in the UK, OSHA and its partners are now fully aligned through research and development, and completely dedicated to removing all barriers to our systemised approach to future housing design and delivery, using the DfMA route now fully adopted and understood, to ensure we reach our targets in volume and performance.

Our business case research also concluded that there is still much confusion afforded by multiple certification, warranty and onsite building control schemes and processes for MMC, with the absence of one ‘level playing field’ and a lack of uniformity, which presents many challenges for contractors, manufacturers and clients. This lack of clear information undermines the concept of the golden thread of information required to understand, manage and mitigate building safety risk. The balance of authority and power is also a moving feast depending on what type of MMC category is used, which also creates uncertainty around cost and margin management for the design teams involved in housing delivery. Further confusion exists in organisations such as UK Finance, where decision and policy makers seek clarification for assessing risk for areas such as securitisation for MMC homes and numerous other financial deliberations.

Common data management of real performance in homes is also a rarity in all areas of housing. The drive for higher performance, such as the Future Homes Standard, will exacerbate the performance gap and lack of data management, if we do not take control over the gaps in performance, lack of governance and contractual arrangement around the delivery of MMC and of course, how we join together in what MMC requires, the seamless DfMA process. Something the automotive industry have been developing for many decades and still developing today. In the housing sector, we still have a way to go to catchup, if we are to make our housing delivery DfMA processes, both robust and risk free.

OSHA and its strategic partners are now developing the opportunity to address these issues (and many more identified areas captured in the OSHA Foundation Business Case), allowing industry stakeholders to remove blockers to wider adoption of MMC, supporting its aims to deliver vast quantities of new homes, create a sense of place, and develop a high-value advanced manufacture cluster. We have concluded our primary and secondary research for some time, and have captured not only the information to proceed to deployment phase, but we have successfully recorded a significant number of existing organisations and stakeholders who have welcomed this collaborative approach, and who are willing to share lessons learned, data capture, and views of the future modus operandi, so we do not waste any time trying to reinvent the wheel, were best in class processes, procedures and indeed information, is already available. The OPC will be a not for profit network hub, not a commercial operation, and so all it seeks to achieve, is a robust mechanism for removing barriers and hurdles for the uptake of MMC, to deliver the homes of the future. Capture of significant real performance data to improve on where we are will come soon after from working with organisations we have already identified as experts in that field. We intend to establish a clear and simple approach to this opportunity with a transparent value proposition for all stakeholders. This will be the first objective of the OPC Steering Group to ensure a sustainable effort and significant deliverables and outputs.

Using the power of an existing network of industry stakeholders and organisations, OSHA and its public sector housing providers, will seek, via the OPC facility, to increase housing delivery with industry by focussing on significant barriers (and opportunities) to drive MMC delivery with the supply chain.

We considered that to prove that the proposed initiative could be a rational and successful intervention, it should be capable of achieving the following aims:

– Delivery Aims:

- Directly supporting the ability of both the client and the supply chain to deliver a greater number of new homes specifically via the OSHA MMC Framework:

- Aggregating technical solutions (especially building configurations)

- Enabling more robust data capture, analysis and management

- Making it easier for clients to engage MMC supplier, thereby making innovative solutions more accessible.

Collaboration aims

- Create (or further support an existing) risk-free environment, encouraging and managing the collaboration of stakeholders from across the whole sector

- De-risk the manufacturing process to ensure better collaboration and efficient DfMA delivery of MMC Homes.

Regional and National aims

- Support public sector housing providers to create a high-value cluster of advanced manufacturing, free form risk and able to capture intelligence gleaned from the OPC

- Align to the expertise already available to unlock new opportunities, including additional OPC hubs for rollout around the UK, onve the OSHA OPC proof of concept has been established and evaluated for its deliverables.

See map below for the network already established and the many stakeholders who are now engaging at OSHA to drive MMC housing delivery, and the delivery support and technology provision team now fully operational at OSHA.

Back to news![Off-Site Homes Alliance [logo]](https://www.oshahomes.org/wp-content/themes/osha-theme/assets/img/osha-logo-2023.svg)