Significant Insight

The Off-Site Homes Alliance collaboration has embarked on a journey of mass customisation, aggregated demand, and the delivery of high quality affordable homes, using the most advanced MMC solutions across the UK and with well crafted and managed DfMA processes.

The OSHA collaboration is built on robust analysis and learning throughout. This starts at its basic form, with ensuring that all parties are around the table at feasibility stage. Then comes the selection of the off-site technologies, the management and operational teams behind them, the composite materials used, the certification, warranty and building control positions, and the overall performance of the systems used. All the way though this interaction is the integration of all contracted parties. It is a journey from the traditional routes we know so well, now through a different lens into the DfMA process that OSHA is managing and demonstrating to its alliance partners nationwide.

It is more about the management of engagement in the DfMA process than anything else, as this is what has stifled the delivery of innovative solutions in the past, for mass affordable and high quality housing delivery.

OSHA working groups, in conjunction with academic partners and the now fully operational OSHA Project Management Office, are now analysing the insight and making recommendations and observations throughout the delivery of each client’s housing projects, based on how they are set up and the amount of resource and knowledge each partner has in house.

A large part of the process is focussed on competency and integration of like-minded stakeholders to ensure a fully coordinated off-site DfMA process. Full certification (e.g., NHBC Accepts, BOPAS etc), warranty provision (where applicable) and building control alignment are again absolutely key to ensuring robust control as the mass customisation takes place with suitable partners. Real performance will be monitored and refined towards achieving zero operational carbon and zero energy designs for the homes provided. Our longer term aims will be to ensure our carbon neutral process is delivered as we improve the quality of our homes and those processes of engagement we role out within the alliance.

Founding OSHA partners believe that the programme of exploration and development has helped us immensely to drive us all forward much faster, much smarter and with a clear aspiration to share that learning together, for the benefit of each and every member. Each partner is now ready for their delivery programmes using the tools and processes developed.

A look back at where we have come from with MMC delivery

MMC and off-site technologies are now recognised as intrinsically linked to achieving higher quality homes that deliver real performance and that reduce energy bills and carbon emissions. This is no longer a perceived fad, it is fact, as is the ability to control the delivery of such systems with significantly improved quality management systems and processes for both securtitisation assurance and certification audit control. In other words a small number of systems, a full volumetric home or manufactured pods rather than 2,000+ individual components in a house, to manage and inspect on site from a plethora of suppliers, the majority of whom do not have a relationship with the company providing the product that sits along side theirs.

DfMA processes used in the automotive industry have come a long way since Henry Ford set up his first factory and it is totally understandable that we should strive to copy this if we want to ensure our biggest investment, is delivered and managed to the best of our ability. a process that is well managed and delivered from a purpose built MMC factory with inspectors and regulators going in to check under controlled conditions, rather than on site trying to monitor thousands of components in a field from potentially hundreds of suppliers.

For the off-site manufacturing industry, who should be applauded for their innovative approaches, it has been extremely difficult and with huge upfront investment costs, to get a strong demand due to the many questions and hurdles. Strict certification and ever stringent regulatory frameworks in the off-site homes sector require a more transparent and a collaborative approach to development.

MMC techniques have been with us for millenniums. dating back to Roman times to build hospitals, training centres and temporary living accommodation for soldiers in the field, with ‘prefabricated kits’.

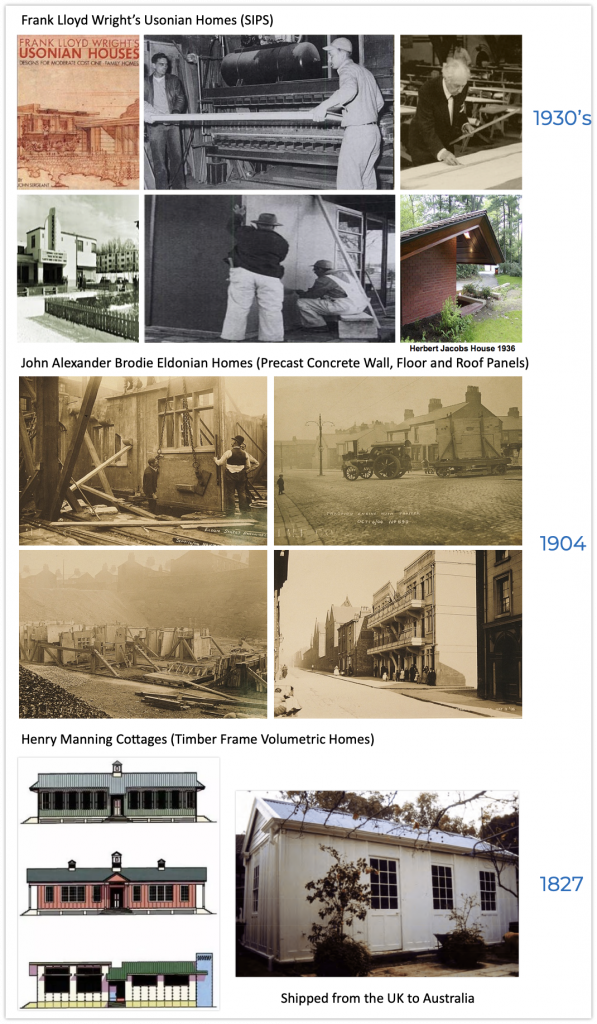

Fast forward to the early 20th century, Frank Lloyd Wright, the famous American architect, developed the use of structurally insulated panels (SIPS) using expanded polystyrene (EPS) and plywood boards, for his Usonian homes back in the mid 1930’s. The Liverpool born civil engineer John Alexander Brodie (responsible for the D&B of the Mersey tunnel), manufactured complex prefabricated concrete panels for social housing apartments (The Eldonian Village) in 1904. He was seen at the turn of the 20th century as a pioneer for modular housing projects around the world. Even as far back as 1827 we saw the Henry Manning Cottage (a full timber frame volumetric home) being shipped from the UK to Australia.

So why then are we still apprehensive around the use of so called Modern Methods of Construction (MMC)?

The fact is that ‘systems‘ rather than endemic and very well understood ”products‘ require deep understanding by all involved, due to their composite behaviours and a lack of historic design standards and associated test methods. We don’t have many UK or European standards for testing systems or indeed full homes and our contracts of engagement are fully focussed on the traditional construction routes. This results in a need for complex certification protocol, insurance risk mitigation, client uptake and aggregation of demand to make it happen.

Careful consideration (often inertia) in MMC or off-site technology use in projects is therefore understandable and can often lead to the need for ‘common approval’ by a host of many stakeholders. This places pressure on the emerging technology manufacturers and their investment partners, who have taken a leap of faith to provide the homes we so desperately need.

The alliance believes that the OSHA initiative will significantly enhance understanding, improve confidence immensely, and allow mass customisation opportunities together with a range of supply chain partners now registered on our OSHA owned and managed MMC Framework.

Without that longer term vision, we may still be chasing small pilot schemes on both sides of the fence, in order to gain that required trust and industry acceptance as a collective. Even then, the insight and lessons learned, may only be shared amongst the few rather than with a much more focussed and intelligent alliance, such as OSHA to share across many influential stakeholders.

Setting a long-term vision for the Off-Site Homes Alliance

An investment partnership (JV) is now very much at the forefront of OSHA’s strategy as is a new R&D network hub now known as the Off-site Performance Centre (OPC). We will be sharing news on both of these in due course.

Recommended reading

Please visit our news section for updates on how the alliance is performing along with industry updates.

![Off-Site Homes Alliance [logo]](https://www.oshahomes.org/wp-content/themes/osha-theme/assets/img/osha-logo-2023.svg)